A Microgrid in California’s Wine Country Keeps the Lights On, and the Tourists Coming

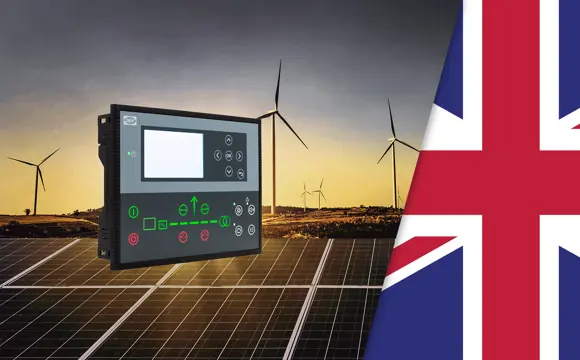

The DEIF AGC 150 controller is vital for a system that seeks independence from a grid that suffers frequent and sometimes forced outages

Thinking of a winery in California’s beautiful Napa Valley conjures up visions of grape vines, wine barrels and tourists, but most people would never think of a microgrid being part of that vision. Yet, running in the background at Castello di Amorosa Winery is exactly that, a microgrid with the DEIF AGC 150 controller playing a critical role in its functionality. Providing confidence and reassurance, the microgrid has become an essential system in their wine making process.

Located about 90 minutes west of Sacramento among the gently rolling hills of Napa, the Castello di Amorosa is known not only for its varieties of wine, olive oils, and wine tasting, but also for its authentically styled 13th century Tuscan castle, which honors the Italian heritage of fourth generation wine maker and founder Dario Sattui. These 171 acres near Calistoga are adorned with the magnificent castle and its 107 rooms that include a gift shop, tasting rooms, restaurant, cellars, chapel, and an armory, all sprawling across 121,000 total square feet. With all the wine production and a constant stream of thirsty tourists, the facility requires a lot of uninterrupted power.

But keeping the lights on can be challenging in California. “We have power outages due to fires, storms in the winter, from someone randomly hitting a telephone pole, any sort of reason,” says Timothy Dexter, facilities manager for the Castello di Amorosa. “Since 2012 we’ve been in a drought, and the fires are just getting worse and worse.”

“I have the utmost confidence in DEIF being able to get the job done. And in collaborating with DEIF’s other partners in this world of microgrids, in making everything work, that’s the scariest thing whenever you’re making a change.”

Timothy Dexter

Facilities manager, Castello di Amorosa

It was the fires of 2017 that motivated the owner of the Castello di Amorosa to make some major changes in how energy generation and distribution were handled onsite. Their generator was knocked offline, leaving the winery without power in the middle of the critical harvest season. With profits and tourist satisfaction on the line, installations of a solar farm, battery storage system, and a new diesel generator were completed.

“The number one issue was sustainability and the environment,” says George Salzner, president of Castello di Amorosa. “We have taken many steps toward being off grid, as we are organic here at the property. The solar system is something we were just looking for to have as a backup. Because we have a lot of power outages here in California, I think that was just a natural step for us to take advantage of the sun here.”

The winery is connected to the PG&E grid, but the effect from wildfires can create power outages that are frequent and at the worst times. To maintain power on the property, the solar farm generates 375kW of power from the sun, along with a 250 kW X 556 kWh energy storage system designed by local firm 127 Energy. An upgraded 250kW 277/480V Diesel Generac unit with paralleling capabilities creates a reliable mix of energy sources that keeps the power on and the tourists coming.

“I was really impressed with Dave (Stringer), the engineer, who was working diligently on setting up the generator in talking to our controller. We are extremely happy.”

George Salzner

President, Castello di Amorosa

“When we have a power outage, the power from the castle comes from the battery and the solar system, and then if the batteries become discharged beyond a certain point, the generator will come online to get the batteries back to their pre-determined rate,” says David Stringer, senior business development manager for DEIF. “The AGC 150 controller is a very important part of the system because without it, if the batteries went down and the sun wasn’t shining, there would be no power during a PG&E outage.”

When a grid failure occurs and power from the diesel generator is needed, the ARC controller from Ageto Energy isolates the microgrid from PG&E. The ARC then sends a signal to the DEIF AGC 150 controller, which starts the generator and, after sensing a normal startup, the operator contactor comes into play, paralleling with the storage system. When the system is no longer needed, the DEIF controller shuts down the generator with a predetermined cooldown period. Such masterful and nearly instantaneous power management is not only automatic, but also easily monitored. “All the protections to the generator, and everything the controller sees, is sent by TCP/IP to the ARC controller so the user can see everything we can see here, except without having to come into the room,” David explains.

Ironically when the microgrid was initially installed, the microgrid faced its first real challenge. “Literally some twenty-four hours after we installed the system, it got one of the harshest tests you could do, with power outages thirteen times over four hours,” says Mark Crowdis, CEO of 127 Energy. “With any power electronics, that can be a real challenge. But within that four-hour period the system went off and turned back on, multiple times, and operated exactly the way it was supposed to.”

With longer and more frequent grid outages, the solar and battery storage system reduces overall fuel costs. As a bonus, the onsite power technology optimizes the microgrid when the microgrid is not providing backup power to the winery, thus reducing power usage during peak-rate times, saving on the facility’s utility bills every month.

Likely the biggest benefactors of such an autonomous system are the facilities personnel. “I sleep easier at night knowing that when the power goes out, the DEIF controller sends the info to the Ageto controller, and the information is sent to my email, saying something happened on the contactor, that we lost power, and knowing we actually had a power outage,” Timothy explains. “It is just more knowledge, more availability of data, and it’s easier to make decisions going forward on what we need, what our power usage is, at what location, and what we need to do to mitigate power issues.”

Timothy gives DEIF a thumbs-up. “They’ve been here the whole time, through the whole process. They had their own challenges with our generator in getting things set up, but they didn’t give up, they just kept on going through it. I would certainly recommend DEIF.”

Read our hybrid power guide

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark